Safety First

Safety is one of DSG Energy’s core values

We maintain an effective safety management system in response to the nature and complexity of the risks in the business. Safety leadership and employee engagement are key focus areas to promote positive behaviours such as intervening in an unsafe situation, recognising positive safety standards, and more importantly, educating our customers to use our products in a safe manner. We promise to continuously improve performance through risk assessment, procedural and engineering controls, training, learning from events and safety culture promotion to our customers.

Using Shell Gas General Safety Tips

To help you ensure a safe environment while using Shell Gas LPG (composed of propane, butane or a mix of them), here are a few brief safety tips :

- LPG is flammable like all petroleum fuels. It must be stored away from sources of ignition and in a well-ventilated area.

- LPG vapour is heavier than air. Any leakage will sink to the ground and accumulate in low-lying areas

- In the event of any leakage, LPG can be detected by a typically unpleasant odour of gas.

- LPG will cause natural rubber and some plastics to deteriorate. Only use hoses and other equipment specifically designed for LPG.

- Although LPG is non-toxic, its abuse is highly dangerous. Treat LPG with caution.

- Purchasing legally sold LPG appliances which contain

mark is recommended.

Piped LPG Safety Tips

Regular Safety Inspections

Reminder from EMSD: Householders should arrange regular safety inspections of gas installations every 18 months.

Maintenance Service

DSG Energy is dedicated to providing a full range of professional inspections and maintenance services, including LPG appliances (spare parts and components charges are not included), internal LPG pipework checking and pressure testing (construction work, renovation, decoration and pipe replacement are not included), and safety advice by registered gas installers to ensure home safety.

Indoor Decoration Work

Avoid damaging concealed pipes and conduits during indoor decoration work.

Cylinder LPG Safety Tips

Safely Storage LPG Cylinder

- Store in a well-ventilated place.

- Do not store in a cellar or enclosed area – LPG is heavier than air and will gather at low-lying areas which form a flammable mixture.

- Never store the cylinders near any heat source or flame.

Connect LPG Equipment Safely

- Always use a rubber hose that is designed for the use with Shell Gas LPG. The rubber hose should have a maximum length of 2 meters with clamps at both ends. Rubber hose should be checked frequently and replaced every 3 years or as indicated on the rubber hose since they deteriorate over time.

- When in use, all cylinders must be equipped with regulators designed specifically for either propane or butane, which will regulate the pressure when temperatures change. Use the correct regulator corresponding with the type of gas.

- Always follow the instructions given when connecting the pressure regulator to the cylinder and do not open the cylinder valve or regulator tap until the pressure regulator is securely attached.

- Never smoke while connecting the equipment and do not check for leaks with a flame.

- Check the regulator or valve before connecting each new cylinder. If the rubber looks worn out or damaged, replace it or contact your supplier.

Using LPG Safely

- Regularly check your rubber hose for signs of damage or cracking.

- Make sure the cylinder is stored upright.

- When the appliance is not in use, turn off the valve or regulator.

- Do not let children handle the cylinders or appliances.

- Arrange safety check and maintenance of your LPG appliances and installation every 18 months.

Empty Cylinders Handling

- Turn off the taps of the connected appliance, then close the cylinder valve or regulator.

- Always return your empty cylinders to your supplier.

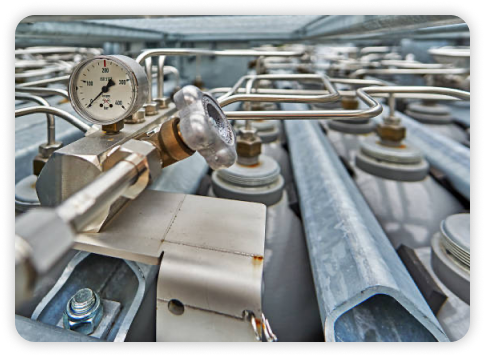

Bulk Tank Safety Tips

DSG Energy will ensure that the LPG tank is located in a safe place and that the necessary devices are in place to protect the tank, pipework and appliances. So, we have implemented a maintenance programme which focuses on maintaining the reliability of gas supply and keeps it operating safely and efficiently.

Emergency Handling of Gas Leaks

Gas Leaks

- Switch off the main valve to cut off gas supply.

- If the situation allows, extinguish all flames immediately.

- Immediately call Shell Gas 24-hr Emergency Hotline 2322 2000 or 999 outside the scene.

Major Leakage or Fire

- Call the Fire Services Department and inform them that the leak or fire involves LPG.

- If the leak or fire is indoor, get everyone out of the premises.

- If the leak or fire is outdoor, evacuate people from the area.

- Call Shell Gas 24-hr Emergency Hotline 2322 2000.

HSSE Commitment and Policy

The safety of our customers, our contractors and our staff are of paramount importance to DSG Energy. Occupational health and environmental issues are also equally important to us. Therefore, our businesses worldwide operate to common standards and follow the same Quality, Health, Safety, Security and Environmental Management System (HSSE-MS), similar in concept to ISO international quality management standards, driving continuous improvement.

Every one of our businesses around the world has a similar policy.

But what does this mean in practice? Here are some examples:

- The equipment that we use in our business is designed, operated and maintained up to high standards.

- Every time a cylinder enters one of our filling plants, it is checked for any damage and corrosion. It will only be filled if it passes the inspection.

- After filling, every cylinder is checked to make sure that there are no leaks and to make sure that it has not been overfilled or under-filled. Only cylinders that pass these checks will leave the filling plant.

- Every cylinder is periodically tested to ensure that it is fit to be used.

- Before filling your tank, the driver will check if it is safe to do so.

- Every tank and its fittings are periodically inspected to make sure that it is in good condition.

- Drivers of vehicles transporting LPG from Shell Gas are trained in good driving practices, emergency procedures, etc.

Material Safety Data Sheet (MSDS)

All of our businesses carry out internal audits to ensure that high standards are met and maintained. Every business is examined by a third party external audit to confirm this, ensuring the management standards are effective with rooms for continuous improvement.

To learn more about our products and materials, you can download the Safety Data Sheet (MSDS) for reference.